We could obtain a fee once you use our affiliate hyperlinks. However, this doesn’t impression our suggestions.

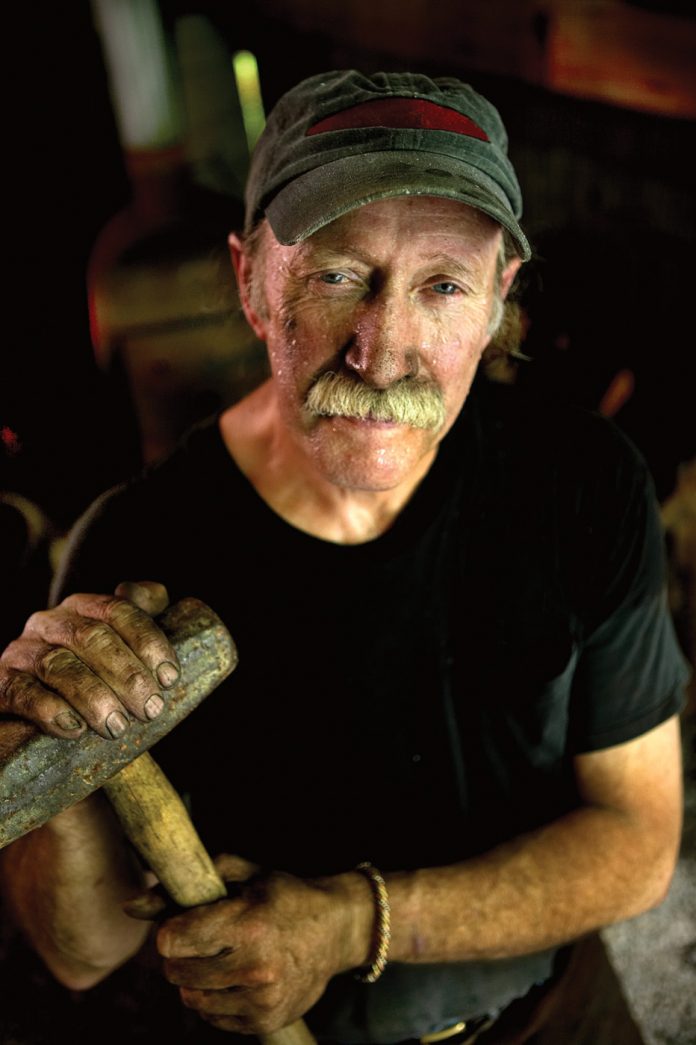

A chairmaker explains his fascination with the traditional artwork of blacksmithing and with the ability to make his personal woodworking instruments.

It was April of 1986, and I’d simply arrived at a craft present up a protracted filth street, an hour’s drive into the redwood-covered mountains of Northern California. I used to be organising my treadle lathe – the normal instrument of the bodger or rural British chairmaker – after I realized that I’d left some essential items of the lathe again dwelling. I didn’t relish the concept of a two-hour journey out and again, however I wanted the elements to do my demonstration.

As if out of nowhere, one other demonstrator on the present, Jon Soini, a blacksmith of Finnish descent, piped up, “Don’t worry, just sit tight – we’ll make the parts.” In much less time than it might have taken to get dwelling – not to mention again – Soini had handforged 4 bolts, nuts and the lathe’s facilities. My lathe was up and operating. I assumed to myself, “I’ve got to get into this.”

As it turned out, Soini’s dream was to construct a wood boat. With my coaching as a joiner and years of chairmaking experiences, I agreed to show him all I knew about working wooden in trade for his educating me what he knew of blacksmithing. For the following six years, we’d get collectively each Wednesday and Saturday (sauna days, not coincidentally) and pound metal at an anvil. Initially I used to be his striker – a laborer who wields a sledge –whereas Soini dealt with the tongs, manipulating the glowing metal on the anvil, presenting the correct face to the hammer, and patiently teaching me all of the whereas. Gradually I discovered the abilities of the smith and started making my very own instruments. When Soini and his household moved as much as the maritime neighborhood of Port Townsend, Wash. (Soini did construct his boat, a 22-foot Seabright skiff), I put collectively my very own modest smithy out subsequent to my chairmaking workshop. I’ve since moved to Paint Lick, Ky., and nowadays I spend a couple of third of my time making chairs, a 3rd blacksmithing and a 3rd educating about and demonstrating the crafts of the bodger.

Forging in Wales

For me, the first lure of the fireplace is with the ability to make any instrument I would like or with the ability to reshape current instruments to go well with my wants as a chairmaker. The attraction goes deeper, although. I used to be contaminated, you may say, at an early age.

As a lad rising up within the village of Llandrindod Wells, within the foothills of the granite mountains of northern Wales, I’d usually discover myself pausing on the door of the forge. In the cruel Welsh winters, the heat and glow of the forge was a welcome cease on the best way to and from faculty. The forge was a magnet not solely to us lads, but in addition to the gents who sat round studying the newspaper and conducting essential village enterprise in that dim, otherworldly, orange glow. But watching the sparks fly and the metal take form earlier than our eyes was the actual motive we stopped by. It was magic then, and it’s magic nonetheless, this remodeling of uncooked iron or metal into recognizable objects of utility.

The Self-sufficient Bodger

My path again to the forge was considerably circuitous. After coming to America within the early 1960s and making an attempt my hand as a farmer exterior of Truth or Consequences, New Mexico, I moved to northern California. There I started making stools and bowls on a treadle lathe. I quickly took an interest within the bodgers and their chairs in addition to within the different rural crafts of 19th-century England. I started making these easy, elegant nation chairs – the predecessors of the American Windsors –however quickly discovered that many of the instruments used to make them had been now not out there. When I met Soini, I knew I’d come full circle.

Being in a position to make my very own instruments – froes, drawknives, spokeshaves, travishers, inshaves and turning instruments primarily – freed me. All of a sudden, I used to be making my very own instruments from outdated truck leaf springs and the like, utilizing these instruments to make a chic chair from logs I pulled out of the firewood pile, after which taking the scrap from the chairmaking and making charcoal for the forge. The independence is exhilarating.

That’s one other factor the agricultural Welshman in me likes – that the instruments and know-how of the blacksmith aren’t, or don’t must be anyway, terribly subtle. As with any craft or interest, you may lay our a fortune simply getting arrange, or you may spend subsequent to nothing and get on with it. That’s my approach – if I can put one thing collectively for nothing, I’m a contented man.

My forge is an outdated riveter’s forge that I discovered on a farm and rebuilt. My furnace is do-it-yourself from firebrick, a bit of an outdated water heater and off-the-shelf plumbing elements. The complete factor value $60. I’ve cast instruments with a charcoal hearth in a barbecue grill and a bellows constituted of a discarded ammunition field. Leaf springs, axles, rake tines – these are all of the uncooked supplies I must make a hammer, knife or chisel. This capacity to make use of what’s readily available has been the reward of the smith in each nation of the world ever since man by chance found iron by constructing a fireplace the place the earth was wealthy in iron ore.

Woodworkers don’t must make their very own instruments, however it may be an enriching expertise. In addition to with the ability to make my very own instruments, {hardware} and different metal fittings, gaining an understanding of the properties of one other materials has helped me perceive wooden – my main materials – in a lot the identical approach that studying a second language improves the understanding of your personal.

Product Recommendations

Here are some provides and instruments we discover important in our on a regular basis work across the store. We could obtain a fee from gross sales referred by our hyperlinks; nonetheless, we now have rigorously chosen these merchandise for his or her usefulness and high quality.